Nuclear waste generated by nuclear power reactors is extremely dangerous to health and the environment for thousands of years.

Nuclear waste generated by nuclear power reactors is extremely dangerous to health and the environment for thousands of years.

Ratepayers and taxpayers fund billions of dollars to store this highly radioactive nuclear waste.

The Nuclear Regulatory Commission (NRC) states the waste may need to be stored at current sites indefinitely.

The NRC evaluated storing spent fuel over three timeframes: 120 years (short-term), 220 years (long-term) and indefinitely.

“Because the timing of repository availability is uncertain, the GEIS analyzes potential environmental impacts over three possible timeframes: a short-term timeframe, which includes 60 years of continued storage after the end of a reactor’s licensed life [of 60 years] for operation; an additional 100-year timeframe (60 years plus 100 years) to address the potential for delay in repository availability; and a third, indefinite timeframe to address the possibility that a repository never becomes available. All potential impacts in each resource area are analyzed for each continued storage timeframe.” Generic Environmental Impact Statement for Continued Storage of Spent Nuclear Fuel Final Report, NUREG-2157, Volume 1, September 2014, page iii and xxx (ML14196A105). Also, significant public comments were received that challenges many of the NRC regarding ability to safely store the waste even short-term. Generic Environmental Impact Statement for Continued Storage of Spent Nuclear Fuel Final Report, NUREG-2157, Volume 2, September 2014 (ML14196A107.pdf)

San Onofre storage canisters may start leaking radiation into the environment as early as 2020, possibly sooner.

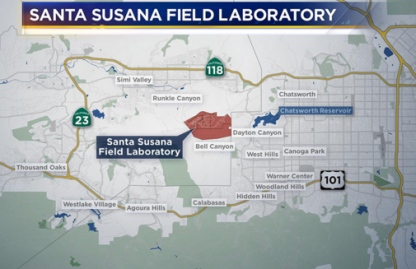

The NRC reported a similar container at the Koeberg nuclear plant in South Africa failed after 17 years from chloride induced stress corrosion cracking (CISCC), triggered by corrosive salt in the marine environment.

Koeberg is located in a similar corrosive marine environment as San Onofre: on-shore winds, surf and frequent fog. The Koeberg container crack length was 0.61″. The San Onofre canisters are 0.625″ thick. The canisters at other California locations are even thinner (0.50″). There are over 2000 loaded canisters in the U.S. Most are 1/2″ (0.50″).

San Onofre started loading canisters with spent fuel in 2003. If San Onofre canisters have experience similar to Koeberg, that means a canister at San Onofre would start releasing radiation into the environment as early as 2020.

NRC documents provide data that indicate thin storage containers can fail 16 years after a crack initiates

The NRC claims fuel must be reloaded into new canisters every 100 years, unless there is a permanent repository. However, they have no technical basis to state these canisters will last 100 years, but they do have data that indicates a much sooner potential failure rate.

None of the current U.S. thin steel storage canisters are adequately designed for over 20 year storage and may start failing in as little as 17 to 20 years with through-wall cracks. Vendor claims of longer storage times are not supported by data. There is no aging management designed into these thin canisters. They cannot even be inspected for cracks or repaired. The NRC lowers safety standards so the utilities can continue using them rather than requiring more robust designs.

Numerous factors can trigger stress corrosion cracks in these thin canisters. Moist salt air is one that the NRC has studied more extensively than the others.

Dry air environments, such as New Mexico, have a corrosive environment that can also trigger stress corrosion cracks in these thin canisters. For example,

KCI(3) Potassium Chlorate (Potash) at all concentrations and at any temperature has severe risk of pitting and crevice corrosion of stainless steels (304/304L/316/316L). See Corrosion Resistance Table for details and other corrosion risks.

Potash is a trade name for potassium bearing minerals used for fertilizer. New Mexico ranks first in U.S. production of potash, amounting to 75 percent of domestic production. Bureau of Land Management – Potash

Potassium Chlorate is a white crystalline solid. It may explode under prolonged exposure to heat or fire. National Center for Biotechnology Information. PubChem Compound Database; CID=6426889, (accessed Apr. 28, 2018)

Documents supporting the above facts and more details are provided on this webpage and elsewhere on this website.

Challenges to implementing a permanent repository, such as Yucca Mountain are significant and the NRC recognizes this.

- Press Release: August 26, 2014, NRC Approves Final Rule on Spent Fuel Storage and Ends Suspension of Final Licensing Actions for Nuclear Plants and Renewals

- NRC decision for indefinite on-site continued storage of nuclear waste website

- The only current geological repository for some types of nuclear waste, the Waste Isolation Pilot Plant (WIPP) near Carlsbad, New Mexico, shut down for years due an exploding waste storage canister that contaminated the facility. Residents were promised it would be safe for at least 10,000 years, but it leaked radiation into the environment in less than 15 years due to a failed steel storage container.

- The cause of the New Mexico nuclear waste accident remains a mystery. However, blaming it on “kitty litter” organic material is questionable. Claims they required only inorganic material be used conflicts with this 1988 study that states sawdust (organic) material was typically used at Los Alamos National Laboratories. See SAND87-7170 Rates of CO2 Production From the Microbial Degradation of Transuranic Wastes Under Simulated Geologic Isolation Conditions, January 1988, page 4: Three types of organic-matrix wastes were investigated for this study: organic composite, sawdust (representative of plywood boxes), and asphalt (also referred to as bitumen, a potential waste encapsulant, widely used for low-level wastes, particularly in Europe). The composition of the organic composite waste material is given in Table 1. This material is typical of transuranic-contaminated (primarily plutonium-contaminated) organic wastes generated at the Los Alamos National Laboratories.

- WIPP waste is stored in thin-wall steel drums that cannot adequately be inspected or maintained and is not designed for long term integrity. See WIPP-016, Rev. 0, Nuclear Criticality Safety Evaluation for Contact-Handled Transuranic Waste at the Waste Isolation Pilot Plant, May 2008, Page 11: Modeled 55-gallon drum wall thickness 0.0478” (0.12141 cm).

- California roads are used to ship some transuranic (TRU) nuclear waste to WIPP. Since 2002, DOE has completed a total of 115 truck shipments of TRU waste in California. See details at Federal Shipments of Transuranic Radioactive Waste in California.

- The Nuclear Waste Technical Review Board (NWTRB) admitted no country has short-term storage and monitoring technology solutions needed to implement a safe permanent geological repository. Webinar, slides and transcript at March 28, 2018 NWTRB Spring Meeting website.

In the NWTRB May 2018 report on Geologic Repositories, the Board admitted “Long-term research, development, and demonstration of monitoring and sensor technologies are needed to address current technology limitations.” In other words, they have no clue how to ever make any geological repository work in the short-term or long term. This myth of a “one and done” permanent storage solution was created by the nuclear industry to justify the economic costs of nuclear power. The reality that there is no long-term solution and the “interim” nuclear waste storage costs will be never ending has not been addressed — even for the short-term. Geologic Repositories: Performance Monitoring and Retrievability of Emplaced High-Level Radioactive Waste and Spent Nuclear Fuel, NWTRB report to Congress, May 2018

- The geological repository being built in Olkiluoto, Finland likely will not work. See Into Eternity.

- The Hanford nuclear waste storage site in Washington has continuous problems with leaking steel containers and the waste has infiltrated groundwater near the Columbia River. Numerous attempts to improve the situation have failed.

- GAO-15-354 report, Hanford Waste Treatment, DOE Needs to Evaluate Alternatives to Recently Proposed Projects and Address Technical and Management Challenges, May 2015

- Washington Examiner article, $19 billion later, 56 million gallons of nuclear waste still untreated, May 6, 2015.

- GAO-15-40 report HANFORD CLEANUP Condition of Tanks May Further Limit DOE’s Ability to Respond to Leaks and Intrusions, November 2014

- 6 more workers sickened by radioactive fumes at Hanford nuclear site, RT, May 4, 2016

Attempts to implement permanent or consolidated interim storage sites for U. S. spent nuclear fuel have failed.

- Civilian Nuclear Waste Disposal, RL33461, Mark Holt, Congressional Research Service, April 24, 2015:

Page 30: Given the delays resulting from the ongoing shutdown of the nuclear waste program, longer on-site storage is almost a certainty under any option. Any of the options would also face intense controversy, especially among states and regions that might be potential hosts for future waste facilities. As a result, substantial debate would be expected over any proposals to change the Nuclear Waste Policy Act, including those of the Blue Ribbon Commission.

Summary: In January 2013, NE [DOE’s Office of Nuclear Energy] issued a nuclear waste strategy based on the Blue Ribbon Commission recommendations. The strategy calls for a pilot interim storage facility for spent fuel from closed nuclear reactors to open by 2021 and a larger storage facility, possibly at the same site, to open by 2025. A site for a permanent underground waste repository would be selected by 2026, and the repository would open by 2048. DOE requested $30 million for FY2016 to develop an integrated waste management system as outlined by the new waste strategy—up from $22.5 million provided for FY2015. The House Appropriations Committee on April 22, 2015, approved $175 million for DOE and NRC to continue the Yucca Mountain licensing process and provided no funding for DOE’s integrated waste strategy (H.R. 2028, H.Rept. 114-91).

- U.S. Court of Appeals for the Federal Circuit, Southern California Edison Company, Plaintiff-Appellee, v. United States, Defendant-Appellant, 2010-5147, Appeal from the U.S. Court of Federal Claims, Case No. 04-CV-109, Judge Lawrence M. Baskir. DECIDED: August 23, 2011, award $142,394,294 to Southern California Edison

Page 3-4: DOE has yet to accept spent fuel from SONGS. Despite the 1987 amendment, the question of where and how the Government will dispose of the wastes remains unanswered to this date. The Government’s current estimate is that it will not begin accepting the waste until 2020, if at all. See S. Cal. Edison v. United States, 93 Fed. Cl. 337, 341-42 (2010).

In 2010, the Secretary of Energy, at the direction of the President, established The Blue Ribbon Commission on America’s Nuclear Future. The Commission’s charge was to conduct a comprehensive review of policies for managing the back end of the nuclear fuel cycle. See Presidential Memorandum of Jan. 29, 2010—Blue Ribbon Commission on America’s Nuclear Future, 75 Fed. Reg. 5485 (Feb. 3, 2010). The Commission has just released its report: “[t]he overall record of the U.S. nuclear waste program has been one of broken promises and unmet commitments.” Blue Ribbon Commission on America’s Nuclear Future Draft Report to the Secretary of Energy, Blue Ribbon Commission on America’s Nuclear Future, July 29, 2011, at xiv, … The Commission further concluded that the recent “decision to suspend work on the [Yucca] repository has left . . . [states and communities across the United States] wondering, not for the first time, if the federal government will ever deliver on its promises.” Id. at 25; see also Mark Maremont, Nuclear Waste Piles Up—in Budget Deficit, Wall St. J., Aug. 9, 2011, at A3 (describing the current and projected federal liabilities associated with the Government’s promise to dispose of the SNF).

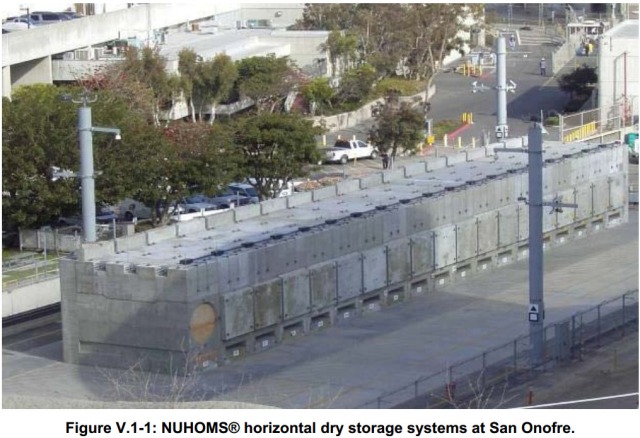

Against this backdrop, it is hardly surprising that in 2001, SCE began constructing dry storage facilities, known as the Independent Spent Fuel Storage Installation (“ISFSI”), for its SONGS-produced nuclear waste. S. Cal. Edison, 93 Fed. Cl. at 346. SCE created its ISFSI facilities to provide on-site storage for part of its SNF rather than to continue using an outside company. Id. Following the construction of the first ISFSI facility, SCE filed a complaint in the Court of Federal Claims seeking damages from the United States as a result of DOE’s breach of the Standard Contract. SCE requested damages in the following categories: costs of constructing and operating the ISFSI facilities; overhead allocated to the ISFSI project; off-site storage of SNF; and costs associated with SCE’s participation in a limited liabilities corporation with other nuclear utilities known as the Private Fuel Storage project.

- Skull Valley, Utah Private Fuel Storage Project failure

- Edison, along with other utilities attempted to create a private fuel storage facility in Skull Valley, Utah. In it’s February, 19, 2009 federal filing, Edison claimed it spent $2,088,656 for the Private Fuel Storage project in Skull Valley, Utah, which has since been abandoned. The PFS project itself has ceased activity and is currently and effectively “dead,” due to the lack of certain required federal agency approvals and state and local political opposition. See Devia v. Nuclear Regulatory Commission, 492 F.3d 421, 425 (D.C. Cir. 2007). Since the cessation of PFS activities, no member has sold or otherwise disposed of its nominal interest in the venture. The PFS LLC was formed in 1996.

- Mescalero Apache Monitored Retrievable Storage Project failure

- Prior to 1996, SCE made payments in support of this project to predecessor companies, including Northern States Power Co. and Mescelaro Fuel Storage LLC. See Sachs, Noah, The Mescalero Apache and Monitored Retrievable Storage of Spent Nuclear Fuel: A Study in Environmental Ethics. Natural Resources Journal, Vol. 36, p. 641, 1996. Available at SSRN: http://ssrn.com/abstract=917190

- Western Governors Association (WGA) Energy Policies include information on some major hurdles that must be overcome before implementation of consolidated interim storage and transport of spent nuclear fuel and other nuclear waste.

- Storage and Disposal of Radioactive Waste and Spent Nuclear Fuel

- Any proposal to store or otherwise dispose of GTCC and high-level radioactive waste and/or SNF [spent nuclear fuel] must be viewed as being part of an integrated program that considers all aspects of necessary operation and intergovernmental considerations. Specifically, transportation and logistical considerations should not be an afterthought to the siting process.

- Transportation of Radioactive Waste and Radioactive Materials

- All current WGA energy policies

- Testimony of James D. Ogsbury, Executive Director, Western Governors’ Association Before the United States House of Representatives Committee on Oversight and Government Reform and the Speaker’s Task Force on Intergovernmental Affairs Oversight Hearing on Federalism Implications of Treating States as Stakeholders, February 27, 2018

- States are not stakeholders. Rather, they are a sovereign level of United States government. States not only created the federal government, but they reserved to themselves the greater measure of authority over public affairs.

- This reservation of power is memorialized in the Tenth Amendment of the U.S. Constitution, which reads in its entirety: “The powers not delegated to the United States by the Constitution, nor prohibited by it to the States, are reserved to the States respectively, or to the people.”

- Storage and Disposal of Radioactive Waste and Spent Nuclear Fuel

- New Mexico Governor Susana Martinez April 10, 2015 letter DOE Secretary Moniz, said she supports consolidated interim storage facility. However, in her letter she erroneously assumes the waste will be safely stored. Here letter assumes because they systems haven’t failed that they won’t fail in the future. The information provided on this website indicates the opposite. She states in the letter “These communities in New Mexico support safely moving spent fuel to a consolidated interim storage site using proven technology which is the most sensible approach to this problem until a permanent and long-term solution is available. Dry cask storage is a proven, passive and safer system that has been used since 1985 with no adverse incidents.“

- EWG’s Ken Cook Testifies On Nuclear Waste Transportation through California and elsewhere, Oct 31, 2007

Do we really have the right to demand that the citizens of the future guard our radioactive rubbish?

Letter to my dear: 3000 generations grandchild to visualize nuclear waste.

.

What can we do to ensure the nuclear waste at all the nuclear plants around the country doesn’t leak radiation into the environment?

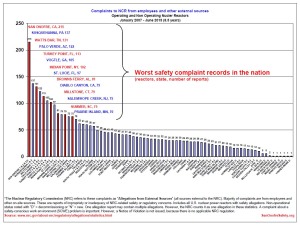

The NRC and Department of Energy (DOE) are overly influenced by the nuclear industry, so we cannot count on them to protect us. The nuclear industry has influence over our Congress (both Democrats and Republicans) and the Senate has control over the NRC’s budget.

It is up to citizens to become educated on the facts and educate other and our elected officials. The public and our local, state and federal elected officials have been given misinformation about the safety of nuclear waste and about the ability to safely store it. All waste storage methods have serious risks, but some are safer than others.

We must insist the waste containers are as safe as possible, that they are designed so they can be easily and reliably monitored and fully inspected as they age, and that there is a realistic mitigation plan, in case of potential failure. That is not happening today. Learn the facts here and then take action now. We don’t have time to waste.

Dry storage containers may crack within 20+ years

Slides from presentation

Link to agenda and all presentation slides from the NRC 2014 Division of Spent Fuel Management Regulatory Conference (DSFM REGCON), held November 19-20, 2014

Link to NRC video archive

This presentation by Donna Gilmore to the NRC on dry cask nuclear waste storage issues was delivered, by invitation, as part of the 2014 annual NRC Regulatory Conference held Nov. 19-20, 2014 in Rockville, Maryland. Why are the NRC and Southern California Edison favoring inferior, short-lived, thin-walled, unsafe stainless steel canisters to store San Onofre’s tons of nuclear waste in a corrosive seaside environment instead of the long-lasting, thick-walled, top-of-the-line technology available?

Gilmore presents a strong case for regulators and utilities to take the lead in setting the highest possible standards for America’s growing inventory of radioactive waste that will remain deadly for hundreds of thousands of years longer than human civilization has yet existed. With no safe long-term storage sites having been found despite over half a century of attempts to find them, Gilmore urges officials not to ‘play bureaucratic roulette’ with the future of California and the rest of the nation.

The NRC technical staff stated the stainless steel nuclear waste dry storage canisters used throughout the U.S. may crack within 30 years from stress corrosion cracking in marine environments. And there is no current technology to inspect or repair these canisters for cracks and no current method to replace these canisters. Other stainless steel products can be inspected and repaired, but that technology cannot currently be used for canisters filled with nuclear fuel waste.

The nuclear waste containers used in the U.S. were not designed to last for more than 20 to 40 years.

- The NRC is evaluating some unresolved critical aging management issues.

- For details on current problems with thin storage canisters and how the NRC is ignoring these, see Donna Gilmore’s response to NRC’s Draft SFM-Interim Staff Guidance (ISG)-2 Revision 2, Fuel Retrievability in Spent Fuel Storage Applications, ocket NRC-20150-0241, November 20, 2015

Stress corrosion cracking can cause thin stainless steel dry storage canisters to fail

NRC metallurgist Darrell Dunn said cracks of the thin (1/2 to 5/8 inch) stainless steel spent fuel containers may grow through the wall in 16 years. This is of particular concern near coastal environments. These dry storage containers are the primary radiation barrier to the highly radioactive spent fuel.

In the August 5, 2014 NRC public meeting on stress corrosion cracking, the NRC stated: “…Based on estimated crack growth rates as a function of temperature and assuming the conditions necessary for stress corrosion cracking continue to be present, the shortest time that a crack could propagate and go through-wall was determined to be 16 years after crack initiation…” See page 4 of meeting summary. August 5, 2014 NRC Chloride Induced Stress Corrosion Cracking Regulatory Issue Resolution Protocol (TAC LA0233) meeting documents.

- Chloride-Induced Stress Corrosion Cracking Tests and Example Aging Management Program, Darrell S. Dunn, NRC (ML14258A082), August 5, 2014

- Summary of August 5, 2014, NRC Public Meeting with the Nuclear Energy Institute on Chloride Induced Stress Corrosion Cracking Regulatory Issue Resolution Protocol (ML14258A081), September 9, 2014

- NRC link to documents for August 5, 2014 NRC meeting (ML14258A087)

Power plant operating experience with stress corrosion cracking of stainless steel shows estimated crack growth rate of up to 0.91 mm (0.036 inch)/year for cold metal. Hotter metal, such as spent fuel dry storage canisters, will have increased crack growth rate, although initiation of the crack may take longer. The Koeberg South Africa plant 304L stainless steel refueling water storage tank (RWST) had multiple cracks up to 15.5 mm (0.61 inch) long within 17 years, which is longer than the thickness of most U.S. canisters (0.61 inch vs 0.50 to 0.625 inch thick). More details on extensive cracks at Koeberg:

- Basson, J.P., & Wicker, C. (2002). Environmentally induced transgranular stress-corrosion cracking of 304l stainless steel components at Koeberg. France: Societe Francaise d’Energie Nucleaire – SFEN.

- Koeberg is a seawater-cooled, 2 x 920 MW Pressurised Water Reactor plant, with a three-loop Framatome nuclear steam supply system. Koeberg is situated 30 km North of Cape Town, South Africa, on the Atlantic coast. Koeberg have detected numerous externally initiated cracks, some through-wall, on seamed piping of safety related systems, the refuelling storage water tanks and cast valves of both units. The tanks, piping and valves are manufactured out of austenitic stainless steel grade 304L and the systems typically operate at temperatures below 50 C. Metallurgical assessment of the cracks concluded it to be transgranular stress-corrosion cracking (SCC) associated with the marine environment (chlorides), susceptible material (304L) and stresses associated with cold forming, welding and casting shrinkage. The cracking was almost exclusively initiated through surface pitting of the components. The problem presented a challenge in that a vast number of components were affected by SCC and due to the largely subsurface nature of the cracking the inspection method had to include grinding of all the pipe surfaces to allow use of dye penetrant testing (PT) to reveal cracks. This paper describes the background to the problem, the inspection method, the morphology and the recovery strategy. Abstract

- Full Koeberg Article

- The Koeberg tank required dye penetrant testing (PT) to reveal cracks. This cannot be done with canisters filled with spent fuel.

- South Africa uses thick (about 14″ thick) ductile cast iron (DCI) cask storage for Koeberg spent nuclear fuel. DCI casks do not have cracking issues.

More examples and details

- NRC presentation on Chloride-Induced Stress Corrosion Cracking Tests and Example Aging Management Program, Darrell Dunn, August 5, 2014 ML14258A082

- Regulatory Issue Resolution Protocol (RIRP) Pilot: Marine Atmosphere Stress Corrosion Cracking (SCC), NRC Sara DePaula and Greg Oberson, April 12, 2012 ML12128A200

The rate of crack propagation is strongly dependent on temperature but is relatively unaffected by stress intensity. Rates of CLSCC propagation can vary from 0.6mm per year at near ambient temperatures to >30mm per year at temperatures ~100 degrees C. See Chloride stress corrosion cracking in austenitic stainless steel, Assessing susceptibility and structural integrity, UK, prepared by the Health and Safety Laboratory for the Health and Safety Executive, 2011 R Parrott, et. al., SK17 9JN (page vii)

Crack initiation is an unknown variable, since the nuclear industry has not been inspecting installed dry storage canisters and has yet to develop a method to inspect them for cracks.

However, a 2014 inspection for sea salts, found sea salt crystals on a Diablo Canyon canister that had only been loaded for two years. Only two Diablo canisters were inspected, ranging from only 2 to 3.5 years in service with heat load of 15 to 20 kW at time of loading. The canister loaded for only two years had sea salts and a low enough temperature range and sufficient moisture to trigger the corrosive environment needed for stress corrosion cracking initiation — much sooner than the NRC expected.

- Understanding the Environment on the Surface of Spent Nuclear Fuel Interim Storage Containers, Charles R. Bryan and David G. Enos, Sandia National Laboratories, PSAM 12, June 2014

- Results of Stainless Steel Canister Corrosion Studies and Environmental Sample Investigations, Charles Bryan and David Enos, Sandia National Laboratories, FCRD-UFD-2014-000055, SAND2014-20347, September 25, 2014 (abundant sea salt found and frequent daily fog).

- California climate zone data shows both Diablo Canyon (Zone 5) and San Onofre (Zone 7) are located in high moisture zones (with on-shore winds, surf, and frequent fog); enough moisture to dissolve salts on the canisters, starting the pitting and cracking process.

Diablo Canyon canisters measured temperatures ranged from 49°C (120°F) to 118°C (245°F). Calculated temperatures ranged from 60°C (140°F) to 105°C (221°F). Lid – measured temperatures ranged from 87°C (188°F) to 97°C (207°F).

Salt deliquescence can occur on interim storage containers only over a small part of the temperature and relative humidity (RH) range that the storage containers will experience. A reasonable maximum possible absolute humidity is 40-45 g/m3; for sea salts, this corresponds to a maximum temperature of deliquescence of ~85ºC. Reference: Data Report on Corrosion Testing of Stainless Steel SNF Storage Canisters, FCRD-UFD-2013-000324, Sandia Lab, September 30, 2013.

- Cracks grow faster in hotter containers.

- Crack initiation at the higher end of the temperature range (up to 80°C) is likely to occur sooner than at ambient temperatures.

Most austenitic stainless steels vessels and piping plant experience with SCC [stress corrosion cracking] suggests that incidence of SCC rises dramatically when temperatures exceed 55-60ºC. Stainless steel items operating above these temperatures are definitely candidates for preventative measures. Stainless steel equipment operating below 55-60ºC will not be totally immune to SCC. (Occasional failures have been reported on ambient temperature equipment after 10-15 years of service).An increase in temperature generally aggravates the conditions for SCC, other conditions being equal. Cracking is more likely to occur at 80ºC proceeding about four times faster at this higher temperature in “wicking” tests compared with 50°C. In tests lasting 10,000 hours each, the maximum chloride concentration to initiate SCC was determined to be about 400 ppm at 20°C and 100 ppm at 100°C. These parameters however will vary with the nature of the specific chloride involved. For example, SCC has been reported at temperatures as low as -20°C in methylene chloride, where the aggressive species was almost certainly hydrochloric acid itself, formed by hydrolysis. Cracked: The Secrets of Stress Corrosion Cracking, Dr. Hira Ahluwalia - Diablo Canyon: conditions for stress corrosion cracking in 2 years, Donna Gilmore

- Crack initiation at the higher end of the temperature range (up to 80°C) is likely to occur sooner than at ambient temperatures.

The NRC has no current mitigation plan for stress corrosion cracks, no adequate inspection plan, and no ability to monitor for helium leaks (which would be an early indicator of canister failure). The NRC frequently follows ASME manufacturing standards. However, ASME does not have spent fuel canister standards for “subcritical crack growth from stress corrosion cracking (SCC), and its impact on inspection intervals and acceptance criteria.” Instead, the NRC said canisters with corrosion and/or SCC must be evaluated for continued service in accordance with ASME B&PV Code Section XI IWB-3514.1 and IWB-3640 (which limits cracks to no more than 75% through-wall). The thin-wall canisters do not have ASME N3 certification. The NRC allows exemptions to ASME standards.

The ability to inspect these canisters for cracks is limited due to inadequate technology. The NRC is allowing 5 years for the nuclear industry to develop an inspection solution. However, the design of U.S. stainless steel sealed canisters (with unsealed concrete overpacks/casks) makes it difficult to inspect even the exterior of the canisters.

- Canisters at higher temperatures will have faster crack growth rate. Sandia Chart below shows higher temperatures can cause canisters to penetrate the wall in less than 5 years. This chart assumes canister wall is 0.625″ (5/8″) thick. The majority of the U.S. canisters are only 0.50″ (1/2″) thick. It is unknown when a crack will start, but these canisters are subject to corrosion and cracking from environment conditions such as ocean salts (chlorides). air pollution (e.g., vehicle exhaust sulfides), pitting, and microscopic scratches. Draft Geologic Disposal Requirements Basis for STAD Specification, A. Ilgen, C. Bryan, and E. Hardin, Sandia National Laboratories, March 25, 2015, FCRD-NFST-2013-000723 SAND2015-2175R, page 46

View larger Crack propagation Chart

Once a crack starts it can grow through canister wall in less than 5 years due to hotter canister temperatures, e.g., 60 degrees C (140 degrees F) or above. Sandia National Lab, 3/25/2015 SAND2015-2175$, page 46

Stress Corrosion Cracking (SCC), NACE International

Stress Corrosion Cracking (SCC) is classified as a catastrophic form of corrosion, as the detection of such fine cracks can be very difficult and the damage not easily predicted. Experimental SCC data is notorious for a wide range of scatter.

A disastrous failure may occur unexpectedly, with minimal overall material loss.

With stress corrosion cracking, usually, most of the surface remains unattacked, but with fine cracks penetrating into the material. In the microstructure, these cracks can have an intergranular or a transgranular morphology. Macroscopically, SCC fractures have a brittle appearance.

Transgranular Chloride SCC in 316SS multi-branched “lightning bolt” transgranular crack pattern, enlarged X300, NACE

This micrograph (X300) illustrates SCC in a 316 stainless steel chemical processing piping system. Chloride stress corrosion cracking in austenitic stainless steel [type used in nuclear waste thin-wall canisters] is characterized by the multi-branched “lightning bolt” transgranular crack pattern.

The catastrophic nature of this severe form of corrosion attack has been repeatedly illustrated in many news worthy failures, including the following:

Swimming pool roof collapse in Uster, Switzerland * EL AL Boeing 747 crash in Amsterdam Stress Corrosion Cracking (SCC) Chloride SCC

Intergranular SCC with crack following the grain boundaries, enlarged X500, NACE

One of the most important forms of stress corrosion that concerns the nuclear industry is chloride stress corrosion. Chloride stress corrosion is a type of intergranular corrosion and occurs in austenitic stainless steel under tensile stress in the presence of oxygen, chloride ions, and high temperature. It is thought to start with chromium carbide deposits along grain boundaries that leave the metal open to corrosion. This form of corrosion is controlled by maintaining low chloride ion and oxygen content in the environment and use of low carbon steels.

Pitting Corrosion, NACE International

Pitting corrosion is a localized form of corrosion by which cavities or “holes” are produced in the material by chemical or mechanical means. Pitting is considered to be more dangerous than uniform corrosion damage because it is more difficult to detect, predict and design against. One cause of pitting initiation is localized chemical or mechanical damage to the protective oxide film; water chemistry factors which can cause breakdown of a passive film are acidity, low dissolved oxygen concentrations (which tend to render a protective oxide film less stable) and high concentrations of chloride (as in seawater).

Apart from the localized loss of thickness, corrosion pits can also be harmful by acting as stress risers. Fatigue and stress corrosion cracking may initiate at the base of corrosion pits.

One pit in a large system can be enough to produce the catastrophic failure of that system. An extreme example of such catastrophic failure happened recently in Mexico, where a single pit in a gasoline line running over a sewer line was enough to create great havoc to a city, killing 215 people in Guadalajara.

Calvert Cliffs dry storage licensed renewed by NRC ignoring safety issues

Calvert Cliffs dry storage facility (ISFSI) license renewed in spite of inability to inspect for cracks or depth of cracks to prevent leaks. Also, no plan in place to deal with leaks. See SOS Calvert Cliffs webpage for additional information and technical reports.

- Calvert Cliffs ISFSI Site License SNM-2505 renewal, October 23, 2014 (ML14274A030) Only visual inspections required which cannot find cracks nor measure depth of cracks, so they will only know after radiation leaks. Not all areas are even accessible. License states: “Remote visual inspections will cover the DSC [Dry Storage Canister] surface areas to the maximum extent practicable“…”In the event of an inspection finding other than acceptable as described in (d)(i) above, the licensee shall issue a condition report in the site corrective action program to drive further evaluation, characterization, and other actions as needed to preserve the DSC intended functions. The cask may not develop through wall cracking or any other through wall breach that places the licensee out of compliance with 72.122(h)(5) [loss of function], and which the licensee is unable to, through corrective actions, return the DSC to its approved design basis. If the licensee identifies such through wall cracking or other through wall breach and is unable, through corrective actions, to return the DSC to its approved design basis, the licensee shall cease use of such cask or submit a license amendment request to modify this license condition.”

- Calvert Cliff Technical Reports

- Calvert Cliffs Stainless Steel Dry Storage Canister EPRI Inspection Report, 2014

- NRC Fourth Request for Additional Information for Renewal Application to Special Nuclear Materials License No. 2505 for the Calvert Cliffs Site Specific Independent Spent Fuel Storage Installation (TAC NO. L24475), ML14175B035, June 23, 2014

Additional stress corrosion cracking information:

- DOE Data Report on Corrosion Testing of Stainless Steel SNF Storage Canisters, Sandia Labs, September 30, 2013

- EPRI Chloride Induced Stress Corrosion Cracking of Spent Fuel Canisters, December 18, 2012 slide presentation (ML13022A316).

- EPRI Update on In-Service Inspections of Stainless Steel Dry Storage Canisters presentation January 28, 2014

- Outside Diameter Initiated Stress Corrosion Cracking Revised Final White Paper, PA-MSC-0474, October 13, 2010, Ryan Hosler (AREVA), John Hall (Westinghouse) (includes San Onofre and others).

- NDE to Manage Atmospheric SCC in Canisters for Dry Storage of Spent Fuel: An Assessment, DOE, PNNL-22495, ML13276A196, September 2013

- EPRI Failure Modes and Effects Analysis (FMEA) of Welded Stainless Steel Canisters for Dry Cask Storage Systems, 3002000815, December 2013, includes dates U.S. casks first loaded (page 2-4 through 2-6)

- Chloride stress corrosion cracking in austentic stainless steel – recommendations for assessing risk, structural integrity and NDE based on practical cases and a review of literature, UK, July 2010

- Flaw Growth and Flaw Tolerance Assessment for Dry Cask Storage Canisters. EPRI, Palo Alto, CA: October 14, 2014. 3002002785

- Critique of EPRI Flaw Growth and Flaw Tolerance Assessment for Dry Cask Storage Canisters, D. Gilmore, May 17, 2015 (EPRI ignored Koeberg and Diablo Canyon data)

- EPRI Literature Review of Environmental Conditions and Chloride-Induced Degradation Relevant to Stainless Steel Canisters in Dry Cask Storage Systems 3002002528, May 27, 2014 The Calvert Cliffs ISFSI is located approximately 3000 feet from brackish water and 65 miles from the open ocean.

- Photos of Stress Corrosion Cracking, Corrosion Morphology

- Non-destructive testing (NDT) educational course material

- Chloride stress corrosion cracking in austenitic stainless steel, Assessing susceptibility and structural integrity, UK, prepared by the Health and Safety Laboratory for the Health and Safety Executive, 2011 R Parrott, et. al., SK17 9JN. The following applies to inspections in vessels and pipes, but indicates the limitations of various inspection options, even in containers without spent nuclear fuel.

…Leak detection is not a reliable indicator of CLSCC [chloride stress corrosion cracking] because cracks are highly branched and may be filled with corrosion products. Nevertheless, it is recommended that where pipework or vessels develop leaks in service, they should always be investigated for possible CLSCC by NDE non-destructive examinations] or by in-situ metallography.

CLSCC can generate very large cracks in structures where, as in the case of reactors, the residual stress from welding dominates and operational stresses are low by comparison. If undetected by NDE, the large cracks might introduce failure modes with consequences that were not anticipated by the original design, e.g. complete separation of attachments, toppling of tall columns under wind loading or collapse of long pipe runs due to self-weight.

The simplest and most effective NDE technique for detecting CLSCC is dye penetrant testing. Eddy Current Testing (ECT) is effective with purpose-designed probes that have been calibrated on known defects. ECT was found to be ineffective on the samples from the reactor due to limited penetration of the current and sensitivity to surface imperfections that could not be distinguished from cracking.

Crack sizing by eddy current testing may be limited and is not possible by penetrant testing.

Ultrasonic flaw detection can be applied as a manual or an automated NDE technique for detecting CLSCC. For structures with complex design features and welds as on the reactors, the trials indicated that ultrasonic testing would require a range of probes, several complimentary scans and be very time consuming. Ultrasonic flaw detection did not cover all design details and possible crack position orientations found on the reactor, and crack sizing was difficult.

Higher temperature increases crack growth rate Darrell Dunn Slide 4

April 21, 2015 NRC and NEI meeting on Chloride Induced Stress Corrosion Cracking and Aging Management.

- CISCC & Aging Management, NRC Darrell Dunn presentation, April 21, 2015

- CISCC Susceptibility Critieria, EPRI presentation, April 21 , 2015

- CISCC NRC/NEI Agenda (ML15097A309), April 21, 2015

- CISCC audio Part 1

- CISCC audio Part 2

- CISCC audio Part 3 (Public comment at 00:45:30)

Factors other than chloride-induced stress corrosion cracking (CISCC) can cause corrosion and cracking in these thin canisters. Environmental and other factors still need to be addressed by the NRC and nuclear industry. For example,

Many storage cask designs utilize ventilation that allows decay heat to dissipate by thermal convection to the atmosphere. Cooler air is drawn into the cask ventilation, passing over the canister with warmer air exiting the cask. The flow of air over the canister also allows atmospheric dust to follow the same path, some of which is deposited on the surface of the canister. The geographic location of the storage facility impacts the composition of dust, with coastal sites containing higher amounts of chloride-bearing sea-salts (EPRI, 2005) and ammonium salts (Enos et al., 2013).

Inland sites containing higher levels of silicate, carbonate and aluminate material impacted by local soil and geology. As the temperature and relative humidity fluctuate at a site, components of the deposited dust (particularly chlorides) can dissolve in absorbed moisture (deliquescence). The dissolved ions are then available to participate in corrosion of the canister. Research has shown that with deposited sea salt, a relative humidity at or above 15% can support deliquescence and subsequent corrosion of the canister steels…

Another factor that can affect corrosion (including SCC) is the presence of gamma radiation from the encased fuel leading to the formation of radials and molecules after radiolysis of the water (and brine) on the surface of the waste canister. Some of the species are highly oxidizing and their reactions in pure water are numerous. In brine solutions, the reactions (and shear number of species) is complex, including radials and molecules of chloride species. Farmer et al. (1988) reviews work performed on gamma irradiation of austenitic stainless steels (such as 304) in water and salt solutions, generally finding that the irradiation increased intergranular SCC even at low chloride concentrations.

LLNL Input to SNL Report on the Composition of Available Data for Used Nuclear Fuel Storage and Transportation Analysis, M. Sutton, J. Wen, Lawrence Livermore National Laboratory, LLNL-TR-659020, August 19, 2014. Used Fuel Disposition Campaign Milestone M4FT-14LL0810044

Frequent Coastal fog at San Onofre and other Pacific Coast locations means dry storage thin-wall canisters are at higher risk for salt induced stress corrosion cracking.

In the ISG-2, Revision 2 NRC Response to Stakeholder Comments (ADAMS ML16117A082) the NRC admits a 2-year old Diablo Canyon canister has a sufficiently low enough temperature for moisture to stay on the canister and dissolve (deliquesce) salts on the canister. However, they then claim there is insufficient humidity along the Pacific Coast for salts to dissolve (deliquesce). They based this on incorrect weather data to reach that conclusion. As stated in this California Climate Zones document, frequently daily fog is common along the San Diego and San Luis Obispo coastline.

The below photo shows such heavy fog you cannot even see the ocean. The photo was taken in San Clemente, about 5 miles north of San Onofre. The photo below the fog photo was taken close to the same spot on a clear evening. Catalina Island is in the distance. Dana Point Harbor is to the right.

Stainless Steel-Nickel Alloys Selection Guide identifies various stainless steel alloys and the advantages and disadvantages of each. It shows the nuclear industry uses 304/304L and 316/316L stainless steel even though they know these alloys are susceptible to stress corrosion cracking:

Stress corrosion cracking (SCC) is one of the most common and dangerous forms of corrosion. Usually it is associated with other types of corrosion that create a stress concentrator that leads to cracking failure.

Nickel containing stainless steel is especially susceptible to chloride induced SCC. Figure 7 (page 16) indicates the maximum susceptibility is in the nickel range of about 5-35% and that pure ferritics, such as Types 430, 439, and 409 are immune. The point of maximum susceptibility occurs between 7-20% nickel. This makes types 304/304L, 316/316L, 321, 347, etc., very prone to such failure.

NRC Proposed Aging Management

The NRC recommends that only one canister at each plant needs to be inspected within the first 20 years after fuel loading and then inspect that same canister every 5 years.

Initially, they are recommending inspection within 25 years in order to give the industry 5 years to develop an inspection solution.

The NRC wants the inspection to occur prior to relicensing and wants it as a condition of licensing.

The nuclear industry doesn’t want to inspect even one canister at each plant and wants the NRC to relicense canisters prior to any inspection of any canisters. See July 14-15, 2014 Meeting to Obtain Stakeholder Input on Potential Changes to Guidance for Renewal of Spent Fuel Dry Cask Storage System Licenses and Certificates of Compliance.

NRC staff plans to revise NUREG-1927, “Standard Review Plan for Renewal of Spent Fuel Dry Cask Storage System Licenses and Certificates of Compliance, March 2011, in May of 2015, now that it’s known the dry storage systems have aging issues and must last for 60 to 300+ years.

The NRC Division of Spent Fuel Management is limiting their aging management research to the thin canister designs, due to budget concerns. They are ignoring the fact that the thick cask designs would eliminate many of the problems that the thin canisters have. Instead, they are setting the safety standards lower.

This November 2014 report, Available Methods for Functional Monitoring of Dry Cask Storage Systems, Xihua He, et.al., outlines the many challenges to develop inspection and monitoring technology or to adapt existing technology to the thin canisters and their concrete overpacks/casks.

…Substantial advancement in technology may be necessary for methods that are not presently designed or packaged for field use…

…No suitable method was identified for detecting and monitoring of atmospheric deposition of solid chloride-containing salts that may lead to degradation of safety significant SSCs, such as welded stainless steel canisters used in the majority of DCSSs…

…Stress corrosion cracking sensors are limited. Surrogate sensors, which are an instrumented SCC coupon, have been developed for condition monitoring in field applications. Significant advancement and qualification testing would likely be necessary to use the sensor for DCSS monitoring. Other methods, such as fiber optic sensors or crack propagation sensors, have significant limitations (e.g., unknown temperature and radiation tolerances). Fiber optic sensors appear to be the only direct method of monitoring the actual component of interest. Implementation of this type of system would be challenging, given the temperatures and radiation near the canister surface. Such an application also would need to consider the possible detrimental effects of attaching a sensor to the canister surface…

…Concrete degradation monitoring methods are well developed and have sufficient sensitivity to detect degradation before physical deterioration begins. However, these methods also have limitations, such as being labor intensive and limited to interrogation depths of 10 cm [4 in] or requiring access to the interior surfaces. Embeddable sensors have been developed and are commercially available; however, significant effort would be required to install these sensors in existing DCSSs. In addition, determining an optimized location for sensor placement may require analysis or knowledge of susceptible areas for degradation…

…Monitoring the canister internal environment poses several challenges because of high temperatures, radiation, and accessibility difficulty…

NRC’s Expert Panel Workshop on Degradation of Concrete in Spent Nuclear Fuel Dry Cask Storage Systems, February 24-25, 2015, identified numerous concrete aging management problems, particularly with below ground systems (such as the Holtec UMAX dry storage system) due to limited inspection capability, ground moisture and chemical reactions with concrete. Concrete is not an issue in thick steel or ductile cast iron casks, since they don’t use concrete for gamma and neutron shielding.

- NRC Concrete Expert Panel Workshop, February 24-25, 2015

U.S. utility companies choose the inferior steel/concrete canister designs due to cost. According to the National Research Council of the National Academies (2006), Safety and Security of Commercial Spent Nuclear Fuel Storage, National Academies Press, Washington D.C., page 63.

The vendors informed the committee that cost is the chief consideration for their customers when making purchasing decisions. Cost considerations are driving the cask industry away from all-metal [thick] cask designs and toward [steel/]concrete designs for storage.

The cost and lack of a solution for the disposal of the steel/concrete canister materials has not been fully addressed. The following report identifies the issues. However, it assumes no canisters or fuel assemblies will leak and cause a higher level of contamination that will make it even harder to dispose of this material. Considerations for Disposition of Dry Cask Storage System Materials at End of Storage System Life, presented by Rob Howard, Oak Ridge National Laboratory, at Symposium on Recycling of Metals arising from Operation and Decommissioning of Nuclear Facilities, April 8-10, 2014

The thin canisters also result in more Carbon-14 into the environment. This is a dangerous and challenging radioactive isotope to manage.

Carbon-14 is a radioactive isotope of carbon and is a pure beta emitter with a half-life of 5730 years; it decays to 14N by emitting low energy beta radiation with an average energy of 49.5 keV and a maximum energy of 156 keV. Carbon-14 is easily transferred during biological processes and soil–plant interactions involving carbon compounds. The metabolism and kinetics of 14C in the human body follow those of ordinary carbon. Inhaled 14CO2 rapidly equilibrates with the air in the lungs and enters many components of body tissue. The biological half-life of 14C is approximately 40 days. It has been found that accumulation of 14C in the human body via respiration is insignificant compared with that from ingestion of contaminated food. In addition, 14C can be easily concentrated in the food chain. Studies have shown concentration factors of 5000 for fish and molluscs and 2000 for soil sediments. Management of Waste Containing Tritium and Carbon-14, IAEA, 2004

It’s not practical to repair a damaged canister, says Dr. Kris Singh, CEO, Holtec International.

“…It is not practical to repair a canister if it were damaged… if that canister were to develop a leak, let’s be realistic; you have to find it, that crack, where it might be, and then find the means to repair it. You will have, in the face of millions of curies of radioactivity coming out of canister; we think it’s not a path forward…

…A canister that develops a microscopic crack (all it takes is a microscopic crack to get the release), to precisely locate it… And then if you try to repair it (remotely by welding)…the problem with that is you create a rough surface which becomes a new creation site for corrosion down the road. ASME Sec 3. Class 1 has some very significant requirements for making repairs of Class 1 structures like the canisters, so I, as a pragmatic technical solution, I don’t advocate repairing the canister.”

Instead Dr. Singh states

…you can easily isolate that canister in a cask that keeps it cool and basically you have provided the next confinement boundary, you’re not relying on the canister. So that is the practical way to deal with it and that’s the way we advocate for our clients.

However, there are many problems with Dr. Singh’s solution of putting cracked and leaking canisters inside [transport] casks.

- There are no NRC approved Holtec specifications that address Dr. Singh’s solution of using the “Russian doll” approach of putting a cracked canister inside a [transport] cask.

- NRC regulations for transport casks require the interior canister to be intact for transport. (Note: the NRC approves non-high burnup fuel in some transport casks, stating it is not credited for containing the waste in an accident. However, this doesn’t address what the receiving site can do with a cracking leaking canister). Requiring an intact canister provides some level of redundancy in case the outer cask fails. Does this mean this leaking canister can never safely be moved? Who will allow this to be transported through their communities? How stable is the fuel inside a cracked canister? The Holtec CIS New Mexico license application states their plan is to return leaking canisters back to sender. However, the senders have no method to replace leaking canisters.

- What is the seismic rating of a cracked canister (even if it has not yet cracked all the way through)? The NRC has no seismic rating for a cracked canister, but plans to allow up to a 75% crack (IWB-3640). There is no existing technology that can currently inspect for corrosion or cracks. The NRC is allowing the nuclear industry 5 years to develop it. It is likely to be inadequate due to the requirement the canisters must be inspected while in the concrete overpacks.

- What is the cost for the transport casks that will be needed for storage? Will they be on-site? Where is this addressed? Transport casks are intended to be reusable because of their higher cost. How and where will they be stored and secured on-site?

- How will the leaking canisters be handled by the Department of Energy at the receiving end of the transport? The DOE must follow the NWPA 1982 safety requirements that requires fuel assemblies to be retrievable from the storage container. However, that is not possible with thin-wall welded canisters. The NRC is ignoring this requirement when approving thin-wall canisters. The NWPA 1982 law only legally applies to the DOE. Numerous proposed legislation for consolidated interim storage attempts to eliminate this and other critical safety requirements for both storage and transport.

A better solution is to use casks that are not susceptible to cracks, that can be inspected and repaired and that have early warning monitoring systems that alert us before radiation leaks into the environment.

Minutes from CEP October 14, 2014 meeting.

Thick casks used in most other countries and some U.S. sites have superior features to the U.S. thin canisters

- Thicker walls (e.g., 10 to 20 inches thick) vs. 1/2 to 5/8 inch thick.

- Ability to remotely monitor for helium leaks.

- Ability to easily inspect the exterior of the canisters.

- Not subject to stress corrosion cracking.

- Not subject to concrete degradation. Concrete overpacks/casks are not needed.

- Robust radiation protection for both storage and transport.

- Reduced cask drop and handling risks results in fewer opportunities for significant radionuclide releases. SANDIA Human Reliability Analysis Informed

Insights on Cask Drops, NUREG/CR-7016, February 2012 (ML110610673), pp 7-1 and 7-2) - Adequate aging management and mitigation solutions.

- Steel/concrete storage systems do not have adequate aging management and mitigation solutions. They were designed without these and technology to address these limitations has not been developed.

- There are inspection limitations with forged steel containers with welded seams. This is not the case for ductile cast iron casks.

- Forged steel: The welds can only be checked by UT, VT, RT. There are no conclusions on the properties of the weld metal and the basic material possible. This can be done only by using a separate sample, which does not have to have the same basic properties.

- Ductile cast iron: Samples out of ductile cast iron containers can be taken either directly from the cask body or from an extra cast-on test block from the same melt, and the same cast. The material properties are the same everywhere. Thus, there are unambiguous characteristic for each container available

- Ductile cast iron casks meet ASME standards for storage and transportation.

- The German ductile cast iron casks (e.g., CASTOR) perform in an exemplary manner and do not have embrittlement issues according to this Sandia National Laboratories report, Fracture Mechanics Based Design for Radioactive Material Transport Packagings Historical Review, SAND98-0764 UC-804, April 1998

The numerous studies cited show that DI [ductile iron] is a well characterized material that does have sufficient fracture toughness to produce a containment boundary for RAM [radioactive material transport] packagings that will be safe from brittle fracture. All the drop tests discussed in this report were conducted using DI packagings and the studies indicate that even with drop tests exceeding the severity of those specified in 10CFR71 the DI packagings perform in an exemplary manner. [page 53]

The use of a fracture mechanics based design for the radioactive material transport (RAM) packagings has been the subject of extensive research for more than a decade. Sandia National Laboratories (SNL) has played an important role in the research and development of the application of this technology. Ductile iron has been internationally accepted as an exemplary material for the demonstration of a fracture mechanics based method of RAM packaging design and therefore is the subject of a large portion of the research discussed in this report. SNL’s extensive research and development program, funded primarily by the U. S. Department of Energy’s Office of Transportation, Energy Management & Analytical Services (EM-76) and in an auxiliary capacity, the office of Civilian Radioactive Waste Management, is summarized in this document along with a summary of the research conducted at other institutions throughout the world. In addition to the research and development work, code and standards development and regulatory positions are also discussed. [Abstract]

The proposed use of ferritic materials for packaging containment has not been without controversy and critics. Ferritic materials, unlike austenitics, such as stainless steel, may exhibit a failure mode transition with decreasing temperatures and/or increasing loading rates from a ductile, high-energy failure mode to a brittle, low-energy fracture mode at below-yield stress levels. Regulators have thus been justifiably cautious regarding the use of ferritics for RAM package applications and have indicated that certification of such packages would require extensive confirmatory research and supporting data (although ferritic RAM packages for storage applications have been certified by the NRC). However, the general conclusion of the research reported herein is that appropriate engineering design methodologies exist which, when rigorously applied to RAM transport packaging conditions and environments, warrant the use of suitable ferritic materials for packaging containment. This report summarizes the Sandia work in support of that conclusion. The report also cites and references parallel research and conclusions of other institutions. [page viii]

Slides from 11/20/2014 presentation

Dr. Wolfgang Steinwarz, Executive Vice President of the German dry cask manufacturer Siempelkamp – whose highly robust nuclear waste storage containers are in use around the world (with only limited use in the U.S.) – explains how his company’s technology is setting a high international bar for safe, long-term radioactive waste containment. Dr. Steinwarz is an internationally renown expert in ductile cast iron technology. This is his presentation from the November 19-20, 2014 NRC Annual Regulatory Conference, held in Rockville, Maryland.

- References for thick cask technology

- Experience with Ductile Cast Iron Fuel Casks, Siempelkamp, Dr. Wolfgang Steinwarz, November 20, 2014 NRC presentation

- BAM Overview of Preparation of a Safety Case for a Dual Purpose Cask for Storage and Transport of Spent Fuel and Recommendations to WASSC and TRANSSC from WASSC/TRANSSC Working Group, Bernhard Droste, BAM Federal Institute for Materials Research and Testing, Germany, Chairman of International Workshop on the Development and Application of a Safety Case for Dual Purpose Casks for Nuclear Spent Fuel, IAEA International Atomic Energy Agency, Vienna, Austria, May 19-21, 2014

- Long Term Storage of Spent Nuclear Fuel and HLW in Dual Purpose Casks towards Disposal – Challenges and Perspectives – Holger Völzke, Dietmar Wolff, (BAM)(Federal Institute for Materials Research and Testing (BAM), June 2015

- CASTOR A High Tech Product Made of Ductile Cast Iron – Siempelkamp Bulletin_2005_2-en

- References-CastorLocationsUsedBrochure

- BAM test results for CASTOR transport containers

- Fracture Mechanics Based Design for Radioactive Material Transport Packagings Historical Review, Sandia SAND98-0764 UC-804, April 1998

- Interim storage of spent nuclear fuel (SNF) and vitrified highly active waste (HAW) in Germany, Christoph Gastl, Federal Office for Radiation Protection, IAEA

Vienna, July 2013 - GNS CASTOR Presentation, June 09-11, 2010, Varna, Bulgaria (slide 18: CASTOR V/19, V52)

- Dry Cask Storage Recommendations to Edison’s Community Engagement Panel (CEP), July 17, 2014

- International Symposiums on the Packaging and Transportation of Radioactive Materials – Index

- Siempelkamp: Ductile cast iron (DCI) seismic and aging, October 27, 2014

- Highest score for Siempelkamp: Container development on the international road to success, (BlueBox, BlueBarrel and TUK-141), June 2014

- Summary of Pre-Application Meeting With Siempelkamp Nukleartechnik GMBH (TAC No. L24696) (Docket No. 71-9369), December 5, 2012

- Experience in preparation of spent nuclear fuel including damaged for shipment, V. Smirnov, et. al., Sosny R&D Company, July 8-10, 2014 (use of leak tight ampoules for damaged fuel, stored in DCI TUK-11 casks). U.S. damaged fuel is stored in unsealed containers (damaged/failed fuel cans)

NRC Branch Chief Aladar Csontos said a cask design similar to the CASTOR V/21 would probably be a safer choice in a coastal environment such as San Onofre, although all canister designs have potential problems.

Germany currently uses a newer version of the ductile cast iron CASTOR cask (CASTOR V/19) and also has some Areva TN-24G thick steel casks made to German specifications. A newer German Areva model TN-24E has a copper exterior layer.

Germany currently uses a newer version of the ductile cast iron CASTOR cask (CASTOR V/19) and also has some Areva TN-24G thick steel casks made to German specifications. A newer German Areva model TN-24E has a copper exterior layer.

TN-24E Areva photo

Germany purchased 70 TN-24E casks in 2013 for a value over $276 million. They house them in hardened buildings that provide additional environmental and radiation protection. Remote monitoring is also provided, unlike U.S. dry storage systems.

.

.

-

Japan has nine thick forged steel casks at Fukushima Daiichi, stored in a building with remote monitoring capabilities. The fuel assemblies all have low burnup (< 24,000 MWD/T or <29,000 MWD/T) with fuel cladding temperature of only 90 -140 degrees C. The NRC allows fuel cladding drying temperatures up to 400 degrees C for high burnup fuel (>45,000 MWD/T) and even higher for lower burnup fuel.

-

The Fukushima casks survived the Fukushima disaster, but are superior to the inferior thin canister U.S dry storage systems and were house in a building.

- Belgium uses TN-24 thick steel casks stored in buildings.

- Areva thick-cask brochure, including where they are used.

- Areva TN-24 metal casks used for transport and storage in other countries including the U.S. (Areva brochure states more than 150 casks

from the TN®24 family have been delivered to U.S. - U.S. sites using thick casks include: Prairie Island for storage and transport (TN-40). Others in U.S. using thick casks for storage include: North Anna (TN-32), McGuire (TN-32), Surry (TN-32, Castor V21 and X33, and Peach Bottom (TN-68). The TN-32 is currently licensed for general use (ML010460291).

- To learn how other countries are managing their waste, see IAEA July 8-10, 2014 Conference presentations.

- Housing casks in buildings would have eliminated cask degradation problems caused by moisture at Peach Bottom and Three Mile Island. See more advantages and details on building storage: Safety Aspects of Dry Spent Fuel Storage and Spent Fuel Management, W. Botsch, et.al, February 24, 2013

- Spent fuel pools are needed to unload failed canisters and cask. However, the NRC allows pools to be destroyed after all fuel is loaded into dry storage, claiming nothing will go wrong. This December 1, 2010 Peach Bottom TN-68 cask event report is an example of why the pools are needed in case of cask or canister failure. [NOTE: The Areva thick steel TN-68 cask worked as designed. It has a lid monitoring early warning system, so casks can be unloaded and repaired (e.g., seal replaced) before a radiation leak. If this had been a thin steel canister that leaked, there is no early warning system and the canister cannot be repaired.]

This micrograph (X500) illustrates intergranular stress corrosion cracking of an Inconel heat exchanger tube with the crack following the grain boundaries. Photo Metallurgical Technologies.

In contrast, NRC’s Darrell Dunn estimates U.S. thin stainless steel canisters may have through-wall cracks within 8 years after the crack appears, due to the higher heat loads allowed in U.S. canisters. He said once a crack appears in a canister, the heat level of the canister determines how fast the crack will spread through the canister.

The NRC is continually approving higher heat loads in dry canisters, increasing the number of spent fuel assemblies allowed in a canister, and increasing allowable fuel burnup and uranium enrichment.

The nuclear plants are shortening cooling times for higher burnup spent fuel, which increases safety risks. The spent fuel pools are overcrowded, so the nuclear plants need to move spent fuel out of the pools in order to make room for more nuclear waste.

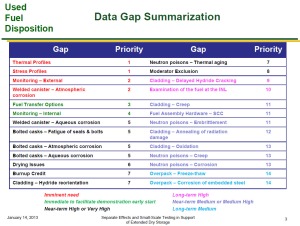

Technical Data Gaps: Unsolved critical issues for nuclear waste storage and transportation

- There are critical gaps in knowledge for safely storing nuclear waste, in spite of the nuclear industry and NRC saying it’s safe. This January 14, 2013 INMM Spent Fuel Management Seminar presentation outlines 26 of these major gaps in knowledge. This includes both short term and long term storage problems and problems in addition to high burnup used fuel [see Data Gap Summarization slide]. Also, the DOE Office of Nuclear Energy (DOE-NE), Office of Fuel Cycle Technology states

“…there are a collective total of 94 technical data gaps identified by the various reports to support extended storage and transportation of [Used Nuclear Fuel] UNF”.

…”Because limited information is available on the properties of high burnup fuel (exceeding 45 gigawatt- days per metric ton of uranium [GWd/MTU]), and because much of the fuel currently discharged from today’s reactors exceeds this burnup threshold, a particular emphasis of this [Used Fuel Disposition Campaign (UFDC)] program is on high burnup fuels.”

- Detailed technical gap reports

- DOE Review of Used Nuclear Fuel Storage and Transportation Technical Gap Analyses, July 31, 2012

- DOE Gap Analysis to Support Extended Storage of Used Nuclear Fuel, January 31, 2012

- NRC Identification and Prioritization of the Technical Information Needs Affecting Potential Regulation of Extended Storage and Transportation of Spent Nuclear Fuel, May 2014 (ML14043A423)

- NRC DRAFT Identification and Prioritization of the Technical Information Needs Affecting Potential Regulation of Extended Storage and Transportation of Spent Nuclear Fuel, May 2012 (ML120580143)

- Dry Transfer Facility (Hot Cell) limitations

- Dry Transfer Systems for Used Nuclear Fuel, Brett W. Carlsen, Michaele BradyRaap, INL/EXT-12-26218, Idaho National Laboratory, May 2012 (addresses needs and current inadequacies for transferring fuel from one canister to another — wet or dry).

- Viability of Existing INL Facilities for Dry Storage Cask Handling, Randy Bohachek et. al., Revision 1, April 30, 2013, Idaho National Laboratory, FCRD-UFD-2013-000027. INL/EXT-13-29035 [for EPRI high burnup demonstration project]

- The only fuel-handling method currently available to the commercial nuclear generating industry is to bring a cask back into a spent fuel pool for reopening.

- Removal of a welded storage cask lid is problematic, and resealing such a cask has never been done. Continued storage and periodic examination of a deheaded cask would be costly and technically challenging.

- 14-ft fuel rods [are] about the longest that can be shipped within U.S. DOT regulations.

- Fuel from new reactor designs (such as the Westinghouse AP1000) will present challenges, because that fuel is just over 15 ft (4.57 m) in length. No shipping cask today can accommodate such a long fuel rod.

- The NRC Commissioners directed staff to “encourage the adoption of state of the art technology for storage and transportation”. Staff Requirements – COMDEK-09-0001 – Revisiting the Paradigm for Spent Fuel Storage and Transportation Regulatory Programs, February 18, 2010 . Instead, the staff has continued to reduce standards, approving storage containers that cannot be inspected, repaired, maintained or adequately monitored.

The staff should undertake a thorough review of the regulatory programs for spent fuel storage and transportation to evaluate their adequacy for ensuring safe and secure storage and transportation of spent nuclear fuel for extended periods beyond the 120 year timeframe considered up to this point. This review should include the standards, regulations, guidance, review processes, and inspection and enforcement procedures. The staff should also undertake research to bolster the technical basis of the NRC’s regulatory framework to support extended periods. The review should identify risk-informed, performance-based enhancements that will bring increased predictability and efficiency to the regulatory processes, and should investigate ways to incentivize these processes to encourage the adoption of state of the art technology for storage and transportation in a risk-informed, performance-based manner. The review should be conducted in a transparent, participatory, and collaborative manner with our stakeholders.

The review should also benefit from experience gained through the Multi-National Design Evaluation Process (MDEP) for reactors and consider opportunities for comparing and, where appropriate, harmonizing, international standards for transport packages and storage casks.

The staff should develop a project plan for Commission approval, including objectives, plans, potential policy issues, projected schedules, performance measures, and projected resource requirements. Such a plan should leverage, as appropriate, improvement initiatives that the staff already has underway.

High Burnup Fuel: Unsafe in storage & transport

Most nuclear plants now use high burnup fuel, which is over twice as hot and over twice as radioactive as fuel originally approve for use by the NRC.

The NRC has so little confidence in the safety of high burnup spent nuclear fuel, they have taken these actions:

-

- No approval beyond 20 years for high burnup dry cask storage.

- No approval for safe high burnup transportation containers. Update: NRC approved two high burnup transport casks by ignoring high burnup risks.

The NRC approved high burnup fuel (greater than 45 GigaWatt days per metric ton of uranium (>45 GWd/MTU)) in the 1990’s based on how it performed in reactors. They did not consider the consequences of storage of the spent fuel. High burnup fuel is low enriched uranium (up to 5% U-235) that is allowed to burn over twice as long in reactors. Experimental data suggests fuel with burnup as low as 30 GWd/MTU shows signs of premature failure. And this November 23, 1976 memo to Prairie Island indicates the NRC was concerned about high burnup (defined then as >20 GWd/tU).

The nuclear industry switched to high burnup fuel because it can burn longer in a reactor, increasing industry profits. However, it reduces our safety.

Nuclear plants’ spent fuel pools are filling to capacity. After densely double racking their spent fuel pools (another safety problem), using high burnup fuel allows them to delay or avoid procuring expensive dry cask storage systems.

This is an example of the NRC and nuclear industry putting profits before safety. See high burnup fuel summary below, followed by government and technical documents that substantiate these facts. Some nuclear experts, even at the NRC, are not aware of all this information.

High Burnup Fuel Summary

-

- No approved short term storage. High burnup fuel is so dangerous and unstable, the NRC will not approved more than 20 years of dry cask storage, even though this deadly waste needs to be stored for thousands of years. Instead the NRC proposes a “demonstration project” that includes requirements for technology that does not yet exist — the ability to monitor the waste inside the dry cask storage system.

No approved safe transportation. The NRC has not approved* safe transportation canisters and casks for high burnup fuel due to potential failures of the protective fuel cladding and the unpredictability and instability of high burnup fuel. The protective cladding around the enriched uranium fuel is becoming brittle, making it more fragile and more likely to shatter. This can release radiation into the environment, risking our safety as well as the safety of nuclear workers. See NRC Interim Staff Guidance – 11, Revision 3 (ISG-11)

No approved safe transportation. The NRC has not approved* safe transportation canisters and casks for high burnup fuel due to potential failures of the protective fuel cladding and the unpredictability and instability of high burnup fuel. The protective cladding around the enriched uranium fuel is becoming brittle, making it more fragile and more likely to shatter. This can release radiation into the environment, risking our safety as well as the safety of nuclear workers. See NRC Interim Staff Guidance – 11, Revision 3 (ISG-11)

- Note: The NRC approved the first high burnup transport cask NUHOMS®-MP197HB (Certificate of Compliance No. 9302, Revision No. 7) on April 23, 2014. However, no justification for this is shared with the public. The entire section regarding high burnup fuel and the section on mitigation in case of an accident were marked “proprietary”. Therefore, public and independent review is not possible. For something that has for years been an unsolved problem, this refusal to share the data justifying this major safety change in NRC’s position is unacceptable.

- NRC Draft Regulatory Issue Summary 2015-XX Considerations in Licensing High Burnup Spent Fuel in Dry Storage and Transportation, April 20, 2015

- Over twice as radioactive. High burnup used fuel is over twice as radioactive as lower burnup fuel. Assumptions made that it would react similar to lower burnup fuel are proving false. For example, see Nuclide Importance to Criticality Safety, Decay Heating, and Source Terms Related to Transport and Interim Storage of High-Burnup LWR Fuel, NUREG/CR–6700, January 2001 (ML010330186).

Requires up to 20+ years in spent fuel pools. High burnup fuel waste is over twice as hot as lower burnup fuel, requiring up to 20+ years in spent fuel pools before it is cool enough to transfer to dry canisters and casks. Lower burnup fuel normally requires 5+ years to cool in the spent fuel pools.

Requires up to 20+ years in spent fuel pools. High burnup fuel waste is over twice as hot as lower burnup fuel, requiring up to 20+ years in spent fuel pools before it is cool enough to transfer to dry canisters and casks. Lower burnup fuel normally requires 5+ years to cool in the spent fuel pools.

- Requires more space for storage. High burnup fuel waste requires more space in a permanent repository than lower burnup fuel because it is over twice as radioactive and over twice as hot. No designs have been developed or approved for this waste.

-

NRC is approving even higher burnup levels. Instead of solving the high burnup storage problems, or stopping use of this unnecessary fuel, the NRC and nuclear industry are raising the maximum allowable burnup from 60 to 62 GWd/MTU. The higher the burnup the more radioactive and the more dangerous. The industry wants to increase the burnup level even higher in order to increase industry profits. And new generation nuclear reactors use high burnup fuel. Note: San Onofre’s high burnup dry storage cask system is approved for a maximum of 60 GWd/MTU.

Burnup as low as 30 GWd/MTU increases risks of cladding damage, which can result in an explosion. If moisture or air enters a storage container with breached cladding, an explosion can result from zirconium hydrides in powder form at a temperature of 270° C (580° F). Specifications require containers to be dry before loading fuel. However, this is subject to errors, accidents and limitations of technology to remove all moisture.